Repetitive Strain Injury (RSI) Awareness Day is February 29th (February 28th in non-leap years). As the only “non-repetitive” day of the year, it’s the ideal date to devote to raising awareness of repetitive strain injuries. RSI Day is a global event which is marked in many countries. We urge all of our locals and regional councils to pass this information on to the membership, to shed light on this far-reaching workplace problem affecting our members.

Sometimes we are so involved in the intricacies of health and safety in our own workplaces that we fail to focus on some of the basics of staying safe. One of the leading causes of workplace injuries across the country involves the hazard of poor ergonomic design which can lead to a Repetitive Strain Injury (RSI).

What are RSIs?

Repetitive Strain Injuries (RSIs) are an umbrella term describing painful ailments affecting tendons, muscles, nerves and joints due to overuse or misuse. RSIs typically affect body parts like the neck, back, shoulders, elbows, forearms, wrists and hands.

Symptoms can progress into chronic and crippling disorders which sometimes cannot be reversed or corrected, no matter the amount of physiotherapy or surgery. RSIs are also known as musculoskeletal disorders (MSDs) and result in the highest frequency of lost-time injuries in Canada.

Work Shouldn't Hurt

Most, if not all of us, have been on jobs where we have experienced some kinds of aches or pains. Perhaps, early in our working lives some of us believed (wrongly) that this tough job assignment was a “normal right of passage.” It was assumed that we would just “get used to the job” and the pain would eventually go away. Far too many of us have suffered for far too long because of this kind of flawed, cultural workplace thinking. While some degree of work-related soreness might be expected for those who have not been physically active, there is a big difference between being sore and being in pain. Quite often, one of the solutions provided by employers is to rotate between problem jobs. However, job rotation is not the answer to addressing the root of the problem and only works to spread the pain.

Using pain relievers, other drugs, narcotics or alcohol is not a viable solution to repetitive strain injuries!

We must embrace the cultural workplace philosophy that “Work Shouldn’t Hurt”

RSI injuries account for more than all other occupationally-incurred injuries combined.

Examples of RSI injuries include:

- tendinitis

- bursitis

- neuritis

- tenosynovitis

- arthritis

- muscle strain

- low-back injury

- herniated disk

- carpal tunnel syndrome

Common symptoms can range from mild to severe and usually develop gradually, including:

- throbbing

- aches and pains

- tenderness

- burning

- tingling

- numbness

- swelling

- weakness

- cramps

- stiffness

- loss of joint movement and strength in the affected area

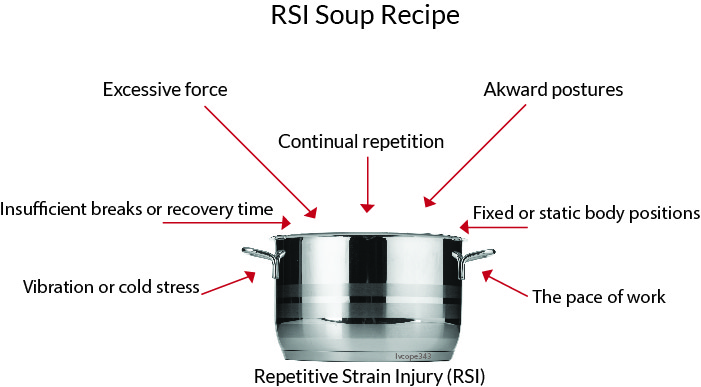

Recipe for RSIs

(Use any or all ingredients)

- Continual repetition

- Awkward postures

- Fixed or static body positions

- Excessive force

- The pace of work

- Insufficient breaks or recovery time

- Vibration or cold stress

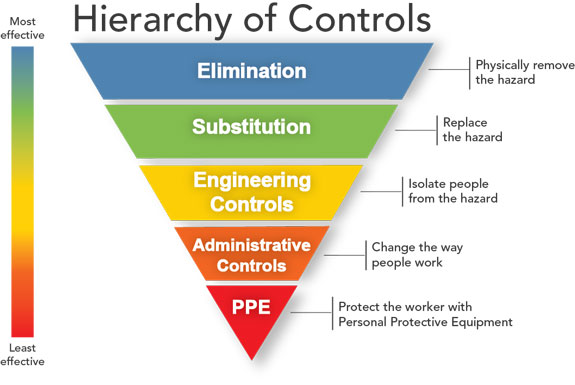

The Hierarchy of Controls

Hazards are best eliminated at their source. The prevention of RSIs begins with eliminating repetitive work through job design. That may involve varied interventions, ranging from product substitution to automation to personal assist devices like hoists or tools. All tools and equipment should be properly sourced and maintained. Well-designed workstations should be adjustable to fit the worker.

What We Can Do as a Union?

RSI Prevention is Better Than the Cure

We need to use the power of collective bargaining to help create the right framework to eliminate the hazards that lead to RSIs. Our collective agreements need to contain ergonomic-related language that call for action to combat ergonomic issues before they arise, and processes to address poor job design on jobs that are injuring our members. Ergonomic checklists, JH&SC investigations and recommendations, joint workplace ergonomic committees, and worker involvement in job station design all are tools that can be used in the prevention and combat of RSIs. The experts in preventing and solving the ergonomic issues are the workers who do or will be doing the work.

Certainly, workers who are suffering from RSIs must be given first aid and medical treatment, and if any lost time is incurred, worker’s compensation benefits. We must ensure that workers understand they have options up to and including, in some cases, the right to refuse unsafe work if they believe that the work they are being asked to do may endanger them from an ergonomic perspective, leading to a repetitive strain injury. Our employers must understand that we will not stand for jobs that are “designed to injure” because of poor ergonomic-related factors.

Here is some model ergonomic language that should be the starting point in every collective agreement

“In addition to the other training specified by this agreement, the employer agrees to ensure that the Joint Health, Safety and Environment Committee is trained in a course or courses to be determined by the committee to enable them to address ergonomic needs on a priority basis and work towards improving the workplace, work station or tool to fit the worker. The employer agrees to pay all associated costs.”

Many Unifor-represented workplaces have negotiated specific ergonomic representatives and national ergonomic representatives. Has your bargaining committee investigated these options?

Our members in the Detroit Three automakers group have arguably some of the best ergonomic language that exists in this country. A quick search of their collective agreements, which are publicly available online, has the word ergonomic used more than 200 times between the three companies’ collective agreements.

The Education Department has developed an extensive course related to ergonomics and we invite you to partake in this training programs if you are able. https://www.unifor.org/member-services/education/introduction-ergonomics-pergo

Our collective agreements have provisions for rest times, break times, holidays, and benefits that are all helpful in making our time at work and away from work. These are some tools that we should use to their maximums. Our collective agreements can be looked at as potential protective health documents. We need to use what we already have and then demand more!

Ergonomic Regulations

Unfortunately, enforceable ergonomic workplace regulations exist in a limited number of Canadian jurisdictions and we must, as a union, continue to press our provincial governments to enact stronger ergonomic protections and standards in our respective occupational health and safety legislation. We have heard from many sources that government health and safety inspectors cannot rely on general duty clauses to address workplace ergonomic issues. Ergonomic improvements and mandated references to accepted standards will help both workers and employers achieve a high standard of workplace health and safety. Political action to improve health and safety legislation must be a top priority.

RSI Day has to be every day!

What is your workplace’s ergonomic action plan?

For more information on RSI Day or workplace ergonomics contact the Unifor National Health and Safety Department at (800) 268-5763/ 416-497-4110 or @email